A US Mint detail many might not know about.

RogerB

Posts: 8,852 ✭✭✭✭✭

RogerB

Posts: 8,852 ✭✭✭✭✭

(This might be a little confusing, but it's something numismatic researchers have to deal with regularly.)

Making coins out of gold and silver is a detail-oriented process. One of those details – things we don’t hear about – has a fundamental influence on reporting mintages.

Put directly, ALL bullion, in ALL forms was accounted for in Troy ounces and grains (or fractions/decimals). Nothing was counted by piece or item until after planchets were struck, defective pieces removed, remaining pieces checked, and sorted into bag lots. At this point, and only this point, were the struck planchets approved by the Coiner and delivered to the Superintendent for his acceptance as good coins. Prior to this, everything was bullion.

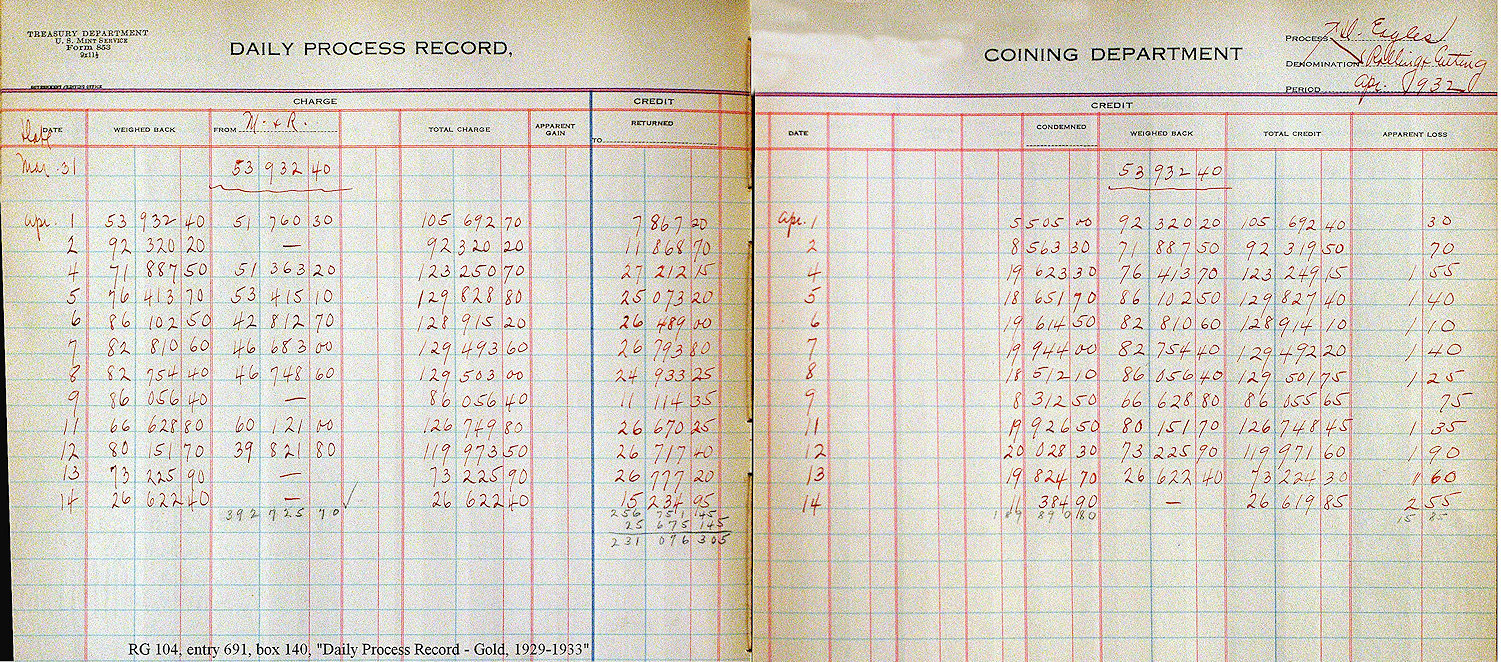

This means that as gold or silver moved from one department or operation step to another, it was tracked by only weight and differences only by changes to weight. The two-page example below shows internal tracking of gold for Double Eagles from the Melting & Refining Department to the Rolling Operation within the Coining Department, and back for each day during the first half of April 1932.

[Read each day from left to right across both pages to see how amounts change.]

All of the numbers are in Troy ounces. To see the complete process to final checking and counting requires 8 pairs of facing pages – and that is only for one denomination.

The practical result is that no one knew exactly how many coins were going to be delivered until they were counted.

One other small wrinkle was this: US Mints did not actually record the number of pieces delivered – they recorded the dollar value of coins. Reported mintages were calculated from dollars – including for proof coins.

Comments

A tedious method indeed... I wonder how many checks and audits were conducted to ensure integrity.... and were there separate ledgers to stipulate losses and causes? Cheers, RickO

Common in other areas, where something is made out of something "larger" and then divided up. Bakeries buy Wheat : ton becomes loaves of bread,

The mint rule was that no one left for the day until their department's books balanced.

Clerks reviewed and compiled data daily, weekly, monthly, quarterly and for the annual settlement. The Chief Clerk (the Superintendent's clerk) and the Computer (title of a clerk trained in handling numbers quickly and accurately) also reviewed data before it went out to the Mint Director. Treasury Dept. Auditors reviewed Mint accounts, although these were mostly expenditures and receipts from sale of old materials, medals, proof coins, etc.

For a more graphic example, look in the Whitman Publishing book. "A Guide Book for Peace Dollars." During research on 1964-D dollars, I found a metal processing diagram that shows the weight of bullion operated on at each step of the process and any gain/loss for that step. I transcribed the diagram and it is shown in the chapter on 1964-D Peace dollars.

Tracing metal by weight was very effective; however, managers never knew exactly how many good coins would result until everything was complete. In a practical sense, no batch of metal ever produced the even numbers of coins shown in official deliveries - there were always "overs" and "unders" carried forward to the next batch.

Roger, how does this compare to today as respects bullion coin production? Is the essential process the same, inserting modern technology?

oldabeintx - No.

The old mint processes were built around end-to-end handling of gold and silver. The US Mints do none of that now.

Planchets are bought from vendors in ready-to-use condition. Each batch is certified to match specifications by the supplier. Specifications include both individual tolerances, piece count and a batch tolerance. The latter ensures Mints not only receive individual planchets that are within tolerance, but that total precious metal in each batch of planchets is equal to what was paid for.

Total reported mintage, of course, excludes defective pieces, and final reconciliation audits account for metal by weight and contract price. Internal losses still occur, but they are small and relate mostly to handling/abrasion of soft gold and silver. Periodic recovery from work areas is also performed.

A "fun fact" -- pure gold bullion is so soft that equipment used to package the pieces in soft plastic is periodically cleaned for recovery of gold. (TPGs that handle large quantities of bullion gold pieces should consider saving and recovering gold particles from gloves and work surfaces.)

Thank you.

I recall seeing something about "sweepings" in one of these mint records, which I assumed was gold and silver dust swept up off the floor.

"Sweeps," as they were called, where not actually the metal dust recovered from sweeping the floors and similar activities. They were the ground up remains of crucibles, pots and other expendable materials used in melting and refining. When these wore out or were broken, they were smashed into small pieces then put into what was called a "Chili Mill" where they were ground into fine particles. This was assayed, packed into kegs and sold to the highest bidder.

You will find this discussed and the mill illustrated and explained in the book "From Mine to Mint."

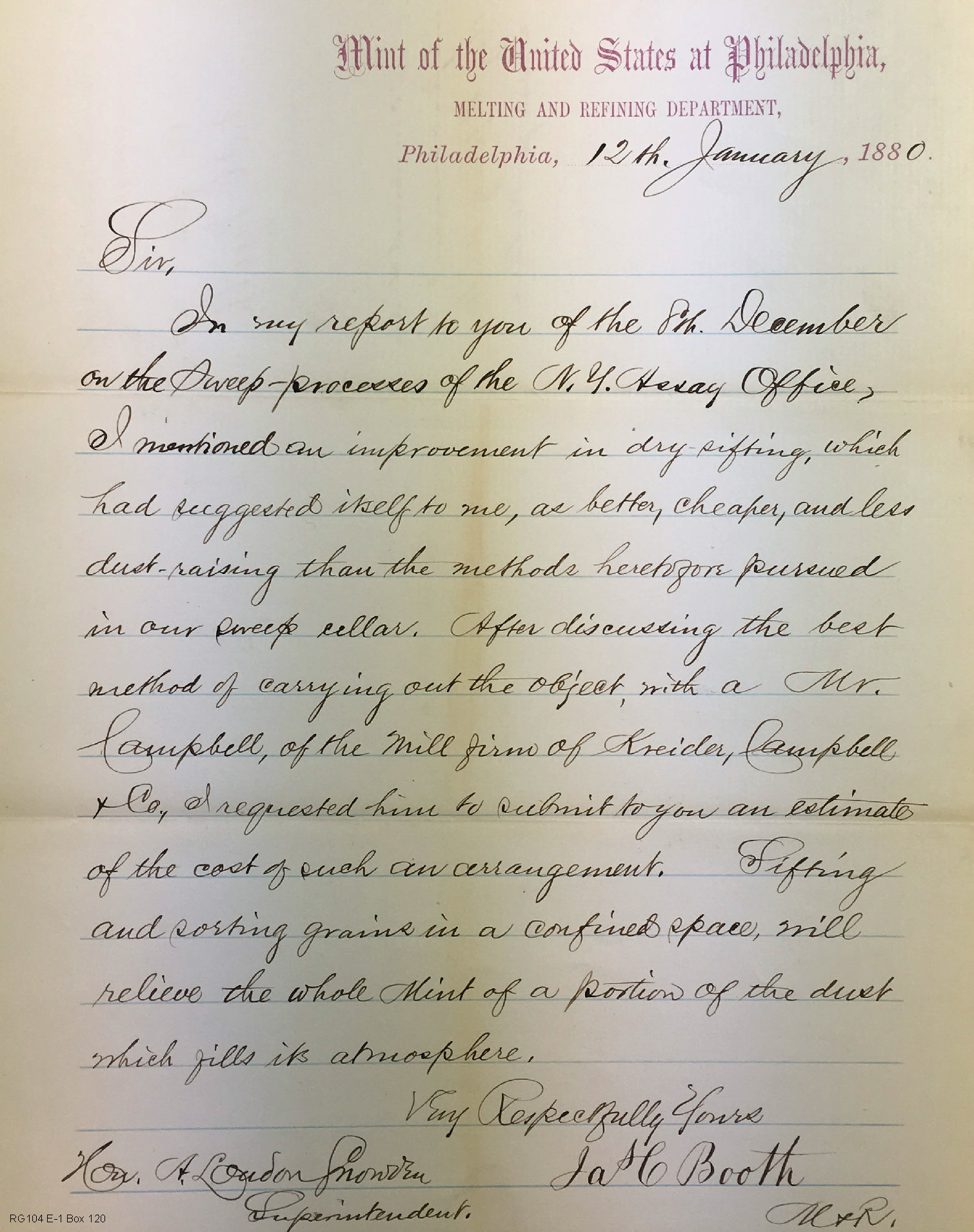

Also, here' a letter discussing the large amount of dust raised by grinding sweeps.

Very much OT, but I always have to admire the beautiful handwriting that educated people displayed back in the day. I had a boss years ago who wrote like this and made a point of sending thank you notes and the like, showing off a bit. Recipients kept these as momentos.

Makes me wonder: did they pay overtime in those days?

RE: "Makes me wonder: did they pay overtime in those days?"

Overtime (often called "extra time" in Mint documents) was paid when the work was ordered by the Director. No one was paid additional if the internal transfer accounts were not balanced. Departments not affected by a discrepancy went home on schedule. Workers signed in (or 'clocked in' once time clocks were available) and out. They were not permitted to leave the building (sometimes the department) during the day, without a written approval from their supervisor.