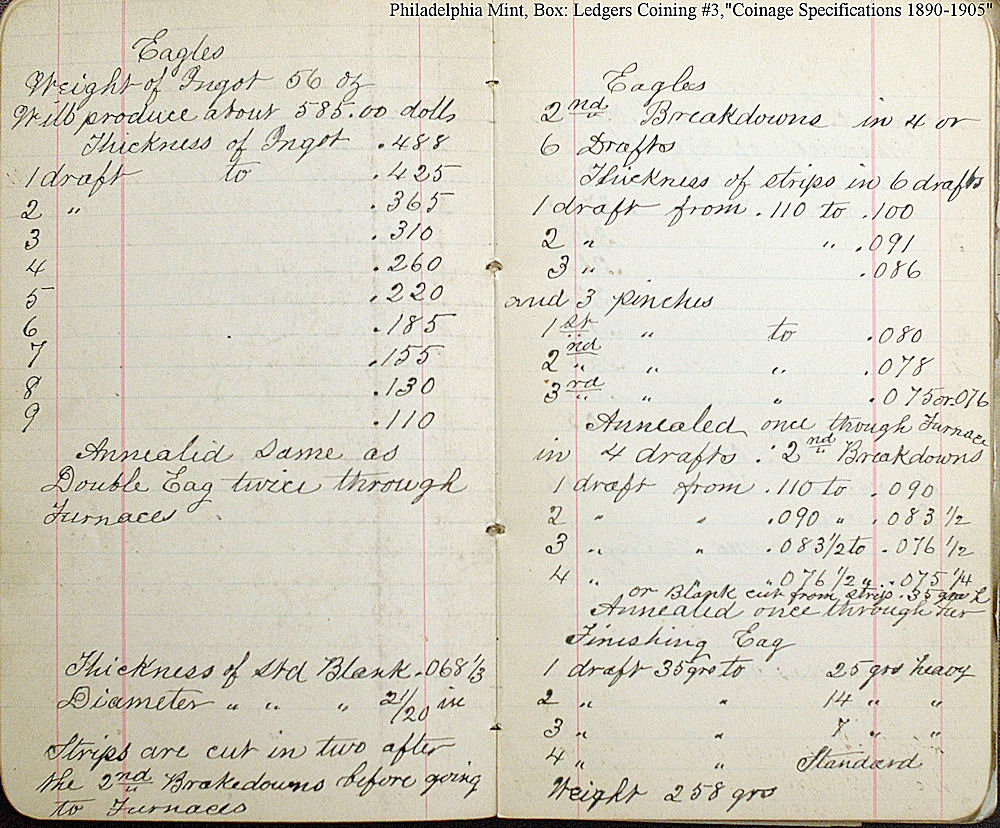

Here's what it took to get a gold ingot ready to make Eagles.

RogerB

Posts: 8,852 ✭✭✭✭✭

RogerB

Posts: 8,852 ✭✭✭✭✭

This is an excerpt from the pocket notebook of someone (probably a foreman) in the Rolling Dept of the Coining Department at the Philadelphia Mint. It took a lot of work to make an ingot ready for cutting blanks.

8

Comments

Kewl!

I owe a lot of my appreciation of the Indian Eagle to one of your books Roger.

I'm gonna save this post for reference.

"Inspiration exists, but it has to find you working" Pablo Picasso

Very interesting... a lot more to it than one would expect.... Cheers, RickO

Hard to follow the last process, I figured once the planchets were cut from the strip they were the correct weight, apparently not.

"Keep your malarkey filter in good operating order" -Walter Breen

Well, you can go for precise thickness and precise diameter to get precise weight, or you can err on the side of caution and make every planchet just a tiny bit heavy and then adjust it down with a file over a collection container to the exact weight.

Neat!

My YouTube Channel

The comments at lower left are apparently a side-note, and not part of the sequence of rolling operations.

From the center, left page "Annealed same as Double Eag twice through furnace," go to the top of the right page and follow the strip thickness to the bottom.

At this period there were three sets of rolls: large "break down" rolls, as on the left page, and smaller "break down" rolls (top of right page). These were followed by smaller "finishing rolls" at bottom of right page where changes are given in grain weight of test blanks rather than inches as shown elsewhere.

"Pinch" refers to a dial on the rolls that was use to make tiny "pinch adjustments" in roll spacing. See** From Mine to Mint** for descriptions and photos showing the dial, etc.

Note that it was not until the early 20th century that steel rolls of sufficient quality became available to allow rolling ingots to near-perfect thickness.

What is really amazing is that all this work on one ingot produced about 58 $10 gold Eagles - there were 500 Eagles to a bag. Look at mintages and you'll get a greater appreciation for what the mint employees accomplished every day.

I have similar tables for 1/4-eagles, 1/2-eagles and double eagles.

Doing the math, I get that the weight of the 58 planchets (assuming all of them are good and there are no clips or other rejects) is approx. 55% of the weight of the ingot.

That's about typical. During blanking, upsetting, weighing and coining, another 10+% of the blanks would get rejected, too.