My big ol' Mossberg

dcarr

Posts: 9,493 ✭✭✭✭✭

dcarr

Posts: 9,493 ✭✭✭✭✭

No, it isn't a shotgun.

But it is more dangerous !

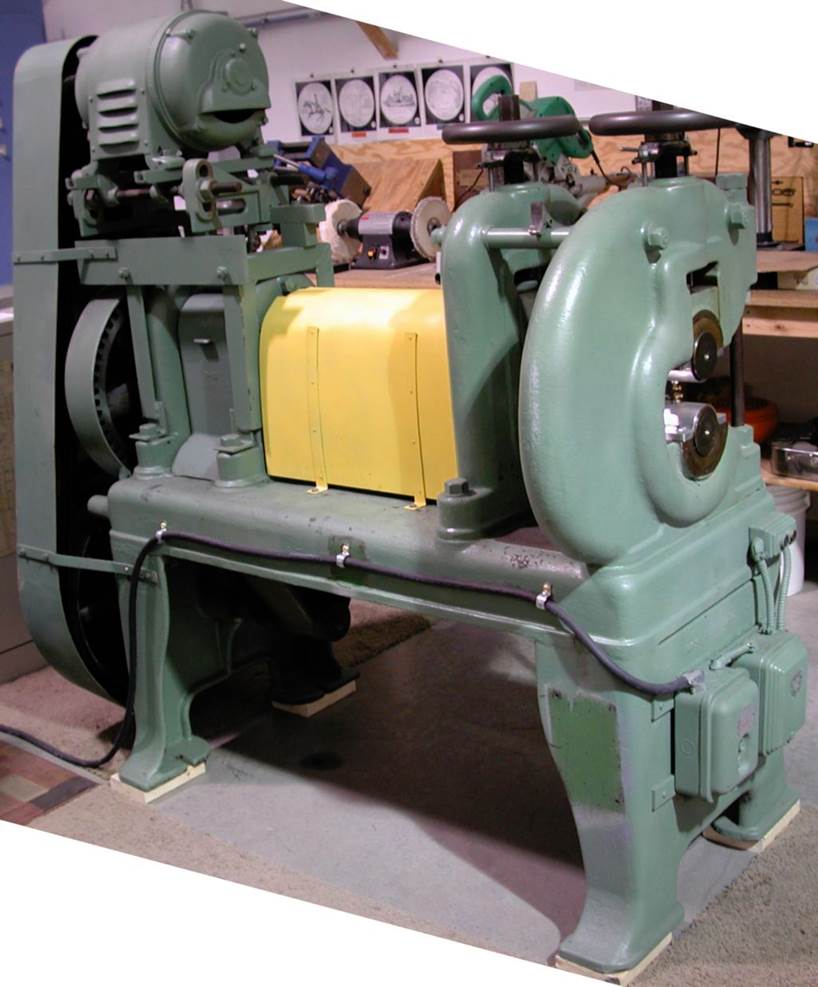

Circa 1894 Mossberg Manufacturing Company rolling mill.

I've been using it the last few months to roll out metal to make my own blanks (such as the 2-troy-oz silver blanks for the WW1 Broken Sword tokens):

This brings up the question of what did the US Mint use for rolling mills. The coin presses are often discussed and written about. But not much seems to be known about the rolling mills. For those that are unfamiliar with this type of machinery, the purpose of it is to roll out an ingot of metal into a sheet from which coin blanks can be punched.

I documented the restoration of my rolling mill here:

moonlightmint.com/equipment.htm

.

20

Comments

Interesting. Thanks for the photos.

very interesting thanks for sharing

How about a video of it in action?...

I like the history

Very cool to see that and can't wait to receive my 2oz!

Given the historical interest of the broken sword reverse, it may be cool to have some photos and videos of the minting process in action.

Tres cool Dan. Were the 2oz Peace the first items for sale using rolled stock from the new beast?

A fascinating piece of machinery.

Would not want to get near that thing. I like my fingers.

bob;)

My kind of mechanics.

Dan, use it in good health.

6:15, Philly Mint, 1940s

3:20, Denver Mint, 1949

There are quite a few videos and photos out there showing the process at the US Mint, for those that want to see it. The process has dramatically changed.

The first thing I rolled out using it was some gold for the 2016 Clark Gruber issues.

I already learned on thing:

Don't wear gloves when pushing a piece of metal through it.

Nice!

I knew it would happen.

Thanks for posting those. I had seen the second video but not the first. I wonder if those were the same type of rolling mills the US Mint used in 1900 ?

Daniel - I am never disappointed opening a thread started by you!

Fascinating as usual!

Last one from me! But there are many more out there if people are interested in seeing the process of minting coins.

But there are many more out there if people are interested in seeing the process of minting coins.

Are you casting small ingots to roll?

circa 1894!

quite an upgrade to retrofit the electrical equipment.

Do the planchets show "roller marks" (striations) from the process?

Very cool!

My YouTube Channel

Yes. I've already been doing that for some 2015 gold and all the 2016 Clark Gruber gold (using my small hand-crank rolling mill). But now I'm doing silver and larger strips.

Cool videos

Nothing better. They don't make 'em like that any more. Give it TLC and grease and it will last forever. I'm jealous. I did buy a Mossberg shotgun once. Jammed every time. I like your new machine Dan.

How did the Mint (and you) keep the strips from getting wider when rolled and only get longer? I assume that there are sidewalls or the like in the rolling chamber, but why doesn't the metal get jammed up against the sides?

Yet in the videos all of the workers feeding the metal are wearing gloves. Must of been a few mishaps for them back in the day.

Must of been quite boring for the ladies back then doing that tedious work of leveling the piles of coins as they hit the conveyor belt. I noticed one lady pulling two coins off the belt and tossing them. Wonder what potential errors/defect may have been on the coin causing her to pull them. Easiest to distinguish for her might of been an off center or clip, if in fact she was looking for those types of errors.

Rolling the metal doesn't make it appreciably wider. It only gets longer. The rollers are about twice as wide as the metal strip.

I should qualify my statement: Don't wear gloves when pushing a short piece of metal through it.

Now I use pliers to hold the metal when feeding into the rollers. The pliers have a blunt end that is too wide for the rollers to grip.

Very interesting Dan... I assume the glove was snatched off your hand. As a very young lad, helping my Mother with the laundry... I got my fingers caught in the rollers that squeezed the water out of the clothes.. painful, but no serious injury... Your machine would have eliminated the appendages - and perhaps a lot more. Cheers, RickO

That's really neat, Dan!

If you get too much more cool equipment like that, that other Denver Mint down the road might be calling you up to help them out when they fall behind in production!

Michael Kittle Rare Coins --- 1908-S Indian Head Cent Grading Set --- No. 1 1909 Mint Set --- Kittlecoins on Facebook --- Long Beach Table 448

I too thought that this was a post about shotguns......

That is a beautiful machine.

Thanks. I did not know that.

That is one beautiful piece of cast iron.

Love the raised letters.

I assume you are using a phase converter for the 5hp motor, or do you have 3 phase power in your shop?

Sweet! Love old machinery. The plants where I worked as a maint. super tech had old DC equipment from the latter part of the 19th century up to the latest CNC machines.

Yep. No damage done, except to the glove (which was totally destroyed).

I chose that particular shop building because it has 208-volt 3-phase power, which is needed for most coin presses.